Electric cars are becoming more and more popular as the world aims to achieve total zero emissions. EV manufacturers primarily focus on components that are environmentally friendly. So, the vehicles typically contain some parts you won’t find in regular cars.Notably, zero emission actuators are among the essential components that help EVs function.

They don’t emit greenhouse gases like conventional actuators might, yet they’re highly efficient. FirgelliAuto shares how they work, the different types, and why these motion devices are important in EVs.

Understanding Zero Emission Actuators

Zero emission actuators are exactly what their name says. These are motion devices that work without releasing greenhouse gases into the atmosphere. As you’d expect, the main aim is to reduce the environmental footprint, and they’re relatively common in electric cars.

Zero emission actuators stand out primarily due to their efficiency. They consume minimal power, which means they don’t draw much power from the car’s battery. Consequently, they help conserve energy.

Furthermore, these motion devices typically feature environmentally friendly materials. So, the focus remains on sustainability right from the production stage.

There are many noteworthy differences when you compare zero emission actuators to regular ones. Conventional motion devices focus more on performance and not sustainability. Hence, they tend to be more power-hungry.

What Makes a Zero Emission Actuator?

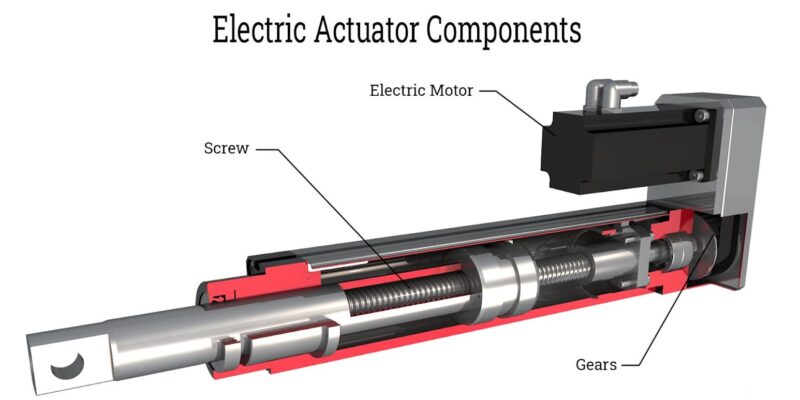

When talking about actuators, the focus is always on electric motion devices. Other types, like hydraulic and pneumatic, can’t fit the description since they have relatively high emission profiles.

For instance, hydraulic actuators use fluids — like fossil fuels — which can emit harmful substances. Similarly, with pneumatic actuators, you have to deal with compressors, and there could be issues with air leaks.

Electric actuators run solely on electricity, so while operating, they don’t release any harmful emissions. As a result, they perfectly fit the description of a zero emission actuator.

Types of Zero Emission Actuators for Electric Vehicles

As explained, electric actuators are the focus when talking about zero emission. Still, they’re of different types. Let’s check them out.

1. Electromagnetic Actuators

These actuators work using magnetic fields generated by currents. When you supply electric power, it forms a magnetic field, which initiates motion. In electric vehicles, these devices are present in systems where precise movements are required. Door-locking mechanisms and advanced brake systems are good examples here.

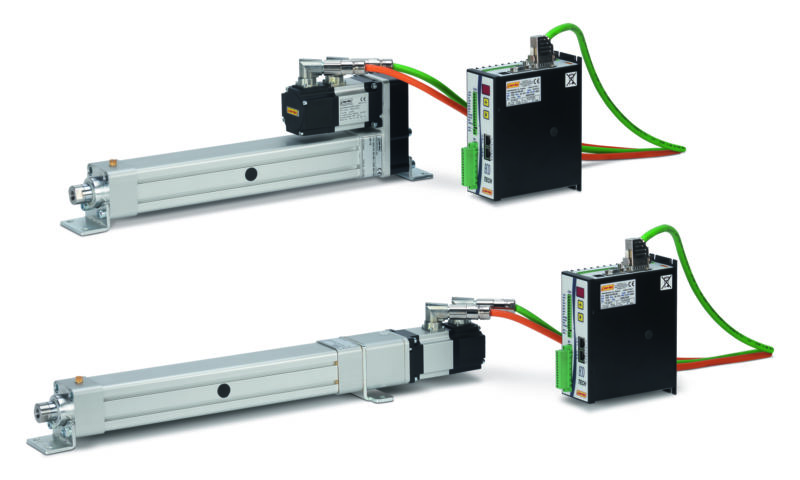

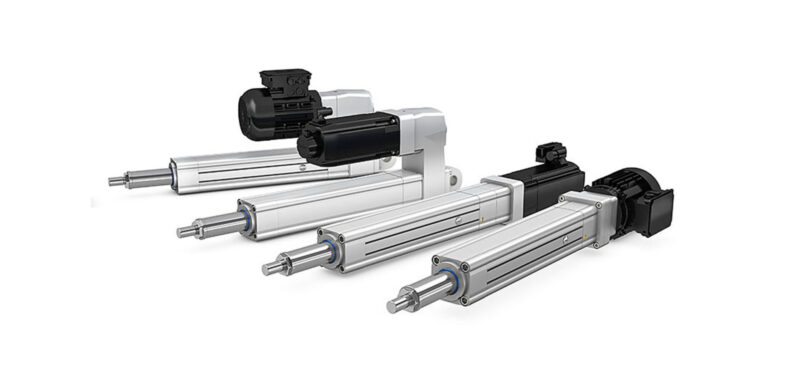

2. Electromechanical Actuators

Electromechanical actuators convert electric energy directly into mechanical motion. Typically, they use an electric motor to create movement, and they have many applications when it comes to electric vehicles. Manufacturers often employ them to adjust seats, mirrors, or power windows, to name a few.

3. Electrohydraulic Actuators

As the name suggests, electrohydraulic actuators combine electric and hydraulic functions. The electric motor in this setup powers a hydraulic pump, and as the fluid moves, the device creates motion. In electric vehicles, these actuators are applicable in advanced suspension systems. Hence, they foster smoother rides by precisely adjusting the suspension to match the road conditions.

4. Electrothermal Actuators

These actuators rely on material expansion and contraction due to heat. When electric current flows through them, they heat up and change shape, and that’s how they produce motion. You won’t find many of these devices in EVs, as their main applications are in thermal management systems. They help ensure batteries and other critical components remain at workable temperatures.

Applications of Zero Emission Actuators in Electric Cars

From the previous section, it’s clear zero emission actuators have many applications in EVs. Let’s discuss some essential ones.

Adjusting Aerodynamics

One chief application of zero emission actuators in electric cars is in the area of aerodynamics. They help adjust parts like rear spoilers or under-car panels. In doing so, the motion devices can optimize the car’s aerodynamic profile. The result is reduced drag, which subsequently ensures the car demands less energy, electric vehicles when running at high speeds.

Thermal Management Systems

Temperature regulation is highly important in electric vehicles. For this reason, manufacturers need optimized parts for control, and they often use actuators. Actuators help adjust components like vents and fans in thermal management systems. Thanks to their precision and efficiency, the motion devices guarantee that the parts remain within specific temperature ranges, and that can improve longevity.

Battery Cooling Systems

EV batteries generate heat, most especially when you’re rapid-charging. Hence, like the thermal management systems, the battery compartment also has vents and coolants. Manufacturers use actuators here to adjust and control these vents and coolants to prevent the battery from overheating.

Regenerative Braking Systems

Regenerative braking stands out as a unique feature in electric vehicles. Instead of dissipating brake energy as heat, this system converts it back to electrical energy. It’s a delicate process that needs optimal control. Hence, devices as precise as actuators come into play, ensuring smooth braking and maximizing energy recovery.

Why Zero Emission Actuators Matter

Zero emission actuators have many environmental benefits. However, the main upside is that they help in minimizing carbon footprint. As mentioned, these motion devices don’t release greenhouse gases or other pollutants.

At the moment, there’s a global push for sustainability. Countries, brands, and even individuals are making efforts to be more eco-friendly with their activities. So, electric vehicle manufacturers are not just improving performance with zero emission actuators. They’re also working towards the global shift.

Furthermore, when it comes to electric cars, it’s all about efficiency. Since zero emission actuators are designed to consume minimal power, they fit the electric vehicle profile perfectly. Drivers get increased range as the actuators consume less battery power. By extension, that also means reduced battery wear over time.

With this, while the main focus is on green, zero emission actuators add more value to electric vehicles.

Bottom Line

Zero emission actuators are currently key in electric vehicles. They handle different tasks and consequently improve performance due to their high efficiency making them fast and stability in high speeds. However, it’s worth noting that these devices aren’t perfect yet. Nevertheless, electric vehicles are still undergoing major developments. So, we can expect significant improvements in zero emission actuators as technology advances.